- 01562744788

- enquiries@central-profiles.co.uk

- Mon - Fri: 8am - 5pm

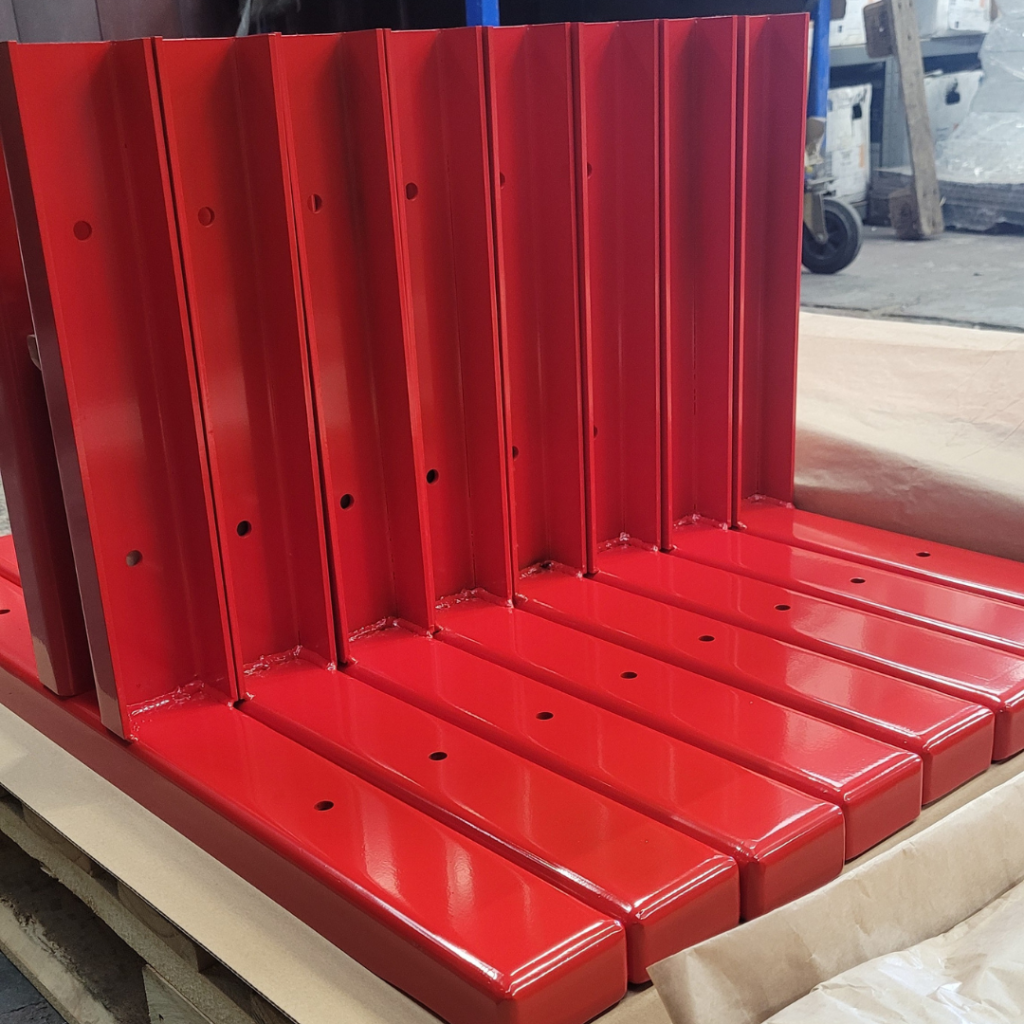

If you’re looking for powder coating services that provide long-lasting and high-quality results, you’ve come to the right place!

Giving an economical and colour durable quality to nearly all types of metal, it’s no wonder powder coating is our most requested metal surface finishing treatment.

Here are 10 of our customer’s most frequently asked questions and answers :

1. What is powder coating?

Powder coating is a way of adding colour to metal and is an excellent alternative to traditional wet paint. Giving a nice aesthetic finish that also protects metal from wear and tear.

2. What can be powder coated?

Powder coating is typically used on metal. Like aluminium, stainless steel, and mild steel. Our customers use it on their industrial, automotive & boiler parts. So many household items are also powder coated.

Powder coat needs to cure at a very high temperature in a specialised oven. So materials like plastic and rubber just aren’t suitable for this process.

3. We require different finishes on our products, can you achieve this with powder coat?

Absolutely, the powders we use are available in a huge range of colours and textures. Our customers commonly request, high- gloss, semi-gloss, matt, and textured. Don’t worry if you’re not sure which powder is best for your product, our powder coaters have decades of experience and are always on hand to offer guidance.

4. How durable is powder coating vs traditional solvent based spray paint?

Powder coating is very durable compared to a typical liquid coating, but only if is it applied correctly. Prep is KEY! So to get the best results we clean the metal thoroughly and apply a pre-treatment before coating the metal.

5. How is powder coating applied?

Our team use a powder coating spray gun which serves the purpose of electrically charging the chosen powder and propelling it towards the parts we want to be coated.

Once the item has been cleaned, pre-treated and powder coat applied all that’s left to do is cure it in a specialist oven.

6. What is the curing process?

In order to strengthen and bond the powder, curing is a must during the powder coating process. Curing involves heating the powder to a specific temperature for a specific amount of time.

Powders cure at different temperatures and can vary depending on the type of coating being applied.

Overall the curing process is relatively quick and most items can be cured in up to 30 minutes.

7. How long does powder coating last?

Different coatings have varying lifespans and each have their own unique properties that will make some powders more suitable and longer lasting for your parts than others. For instance, some powders are not resistant to UV light and for this reason, wouldn’t be the best choice for garden decor products.

8. I’ve heard powder coating is environmentally friendly, is this true?

One of the key advantages powder coating has over many other finishing processes is how safe it is for the environment and most importantly, our team too.

Powders are not only solvent free but overspray can also be re-used. Resulting in less waste.

9. Is powder coating a more expensive process than traditional spray paint?

The truthful answer is yes. However, in terms of durability, powder coating is unmatched and it lasts much longer than the average coat of paint.

Buy cheap, buy twice they say!

10. Are there any disadvantages to powder coating?

From a customer’s point of view, I don’t think there are any disadvantages to powder coating.

Powder coated parts are extremely easy to maintain, resistant to chipping and protect your parts from corrosion and rust. So a great all-round finishing treatment.

Hopefully i’ve answered all of your questions but for more information, get in touch with our team today!

Social Media and Customer Service Assistant

04/07/2022

We started out in 1999 and have grown continually through an ongoing investment in machinery, software and people, even during the downturn.

© 2021 Central Profiles. All Rights Reserved. Website by Freestart Digital