- 01562744788

- enquiries@central-profiles.co.uk

- Mon - Fri: 8am - 5pm

Robotic welding, what is it? Well, the clue is in the name…. a robot that welds!

You may also ask, why do we need them when we have lots of skilled craftsmen and women that have perfected this profession. The truth is robots can weld faster, cheaper, and are more efficient as they eliminate potential errors that humans can generate.

But how are they quicker?

People require breaks, legally and morally. Even the most experienced welder needs a regular cuppa, robots however can keep going and going….. no toilet break required.

So whilst they do not necessarily weld quicker, their higher percentage of uptime significantly increases productivity on a daily basis. The only time you’re likely to see an issue is if they need a part replaced.

Robots are also not susceptible to fatigue like human workers are. They will just keep working with the same level of attentiveness until the project is complete, so they are ideal for repetitive motions applied to a large volume of parts.

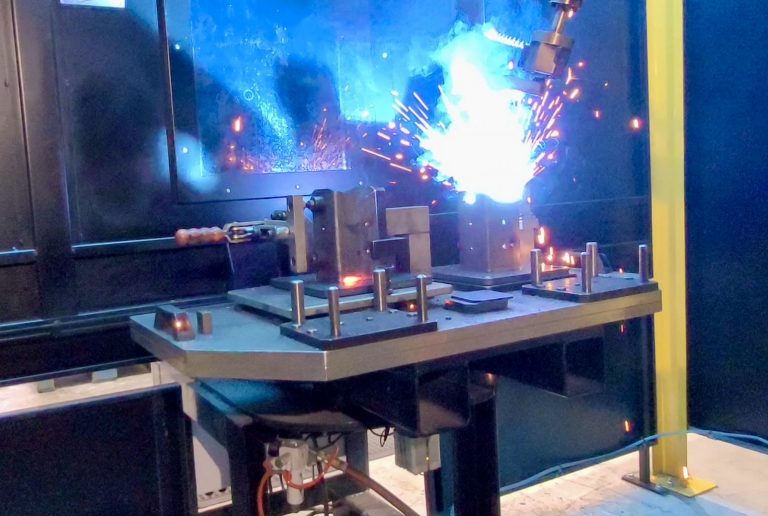

Another fantastic advantage is there is less of a clean-up process vs manual welding, as the precision of the robots also reduces spattering, resulting in neater joins.

Are they safer for employees too?

Absolutely! There are numerous safety risks with manual welding, such as welders flash (eye burn) and even respiratory problems due to the harmful fumes inhaled. Adequate controls to protect our welders from any risks will always be our top priority but manual welding will always be more hazardous than robotic welding.

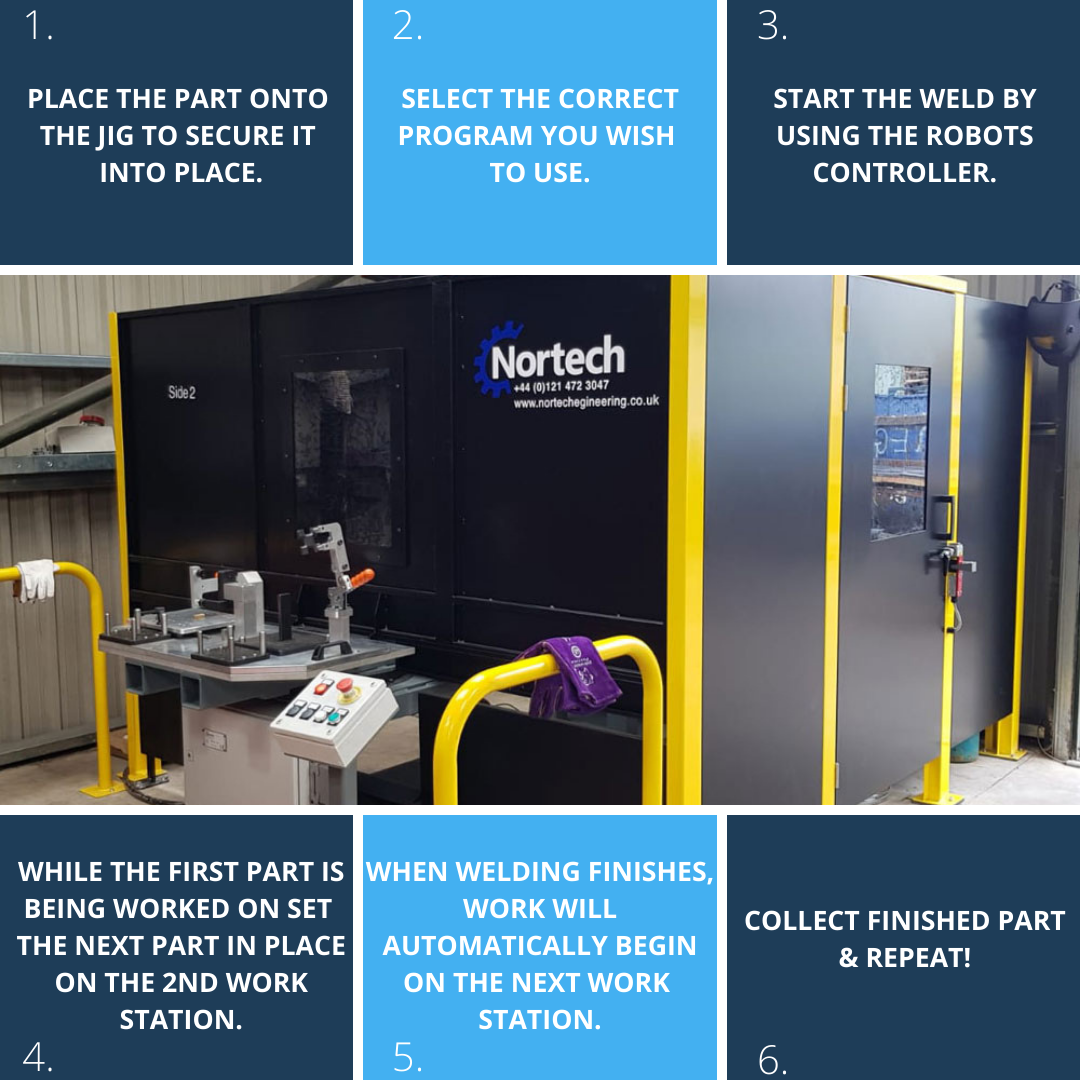

I’ve talked about how amazing robotic welding is but it isn’t suitable for every weld. Robots can perform the same tasks repeatedly but when you need them to start a new project, they must be reprogrammed and the jigs will also need to be replaced which takes time.

Jigs are used to precisely and firmly position parts while they are welded and typically custom made, for each part.

Is it cost efficient to do small volume orders?

Yes, but the cost impact is much greater on large batches of work, so for smaller orders, we would highly recommend our talented manual welders.

Want to know the difference between the available styles of weld? Keep an eye out for next weeks blog post 💥

.

16/07/2021

We started out in 1999 and have grown continually through an ongoing investment in machinery, software and people, even during the downturn.

© 2021 Central Profiles. All Rights Reserved. Website by Freestart Digital